External Balancer

Fully automatic operation means you no longer need to pre-balance grinding wheels, and eliminates the need for awkward equipment, which only does part of the job. Fully automatic operation means you no longer need to pre-balance grinding wheels, greatly reducing set-up time and ensuring a smoother running, more efficient grinding operation.

Systems are available to fit machines with wheel diameters from 6” to 48”. They interface with CNC machines and can be designed into every QC/SPC program which includes grinding. You purchase the SBS System as a retrofit package or as an option from most machine tool builders and rebuilders.

SYSTEM PRINCIPLES

The system operates on a principle of mass compensation for wheel imbalance. The balance head contains two movable eccentric weights, each weight is driven by electric motors through a precision gear train. These weights can be repositioned to offset any imbalance in a grinding wheel.

UNBALANCED BALANCED

Imbalance or vibration is picked up by the sensor. The signal is fed to the controller, which filters the signal by RPM. The controller then drives the two balance head weights in the direction that reduces the amplitude of the vibration signal. When the weights are positioned so the lowest vibration level is reached, the balance cycle is complete.

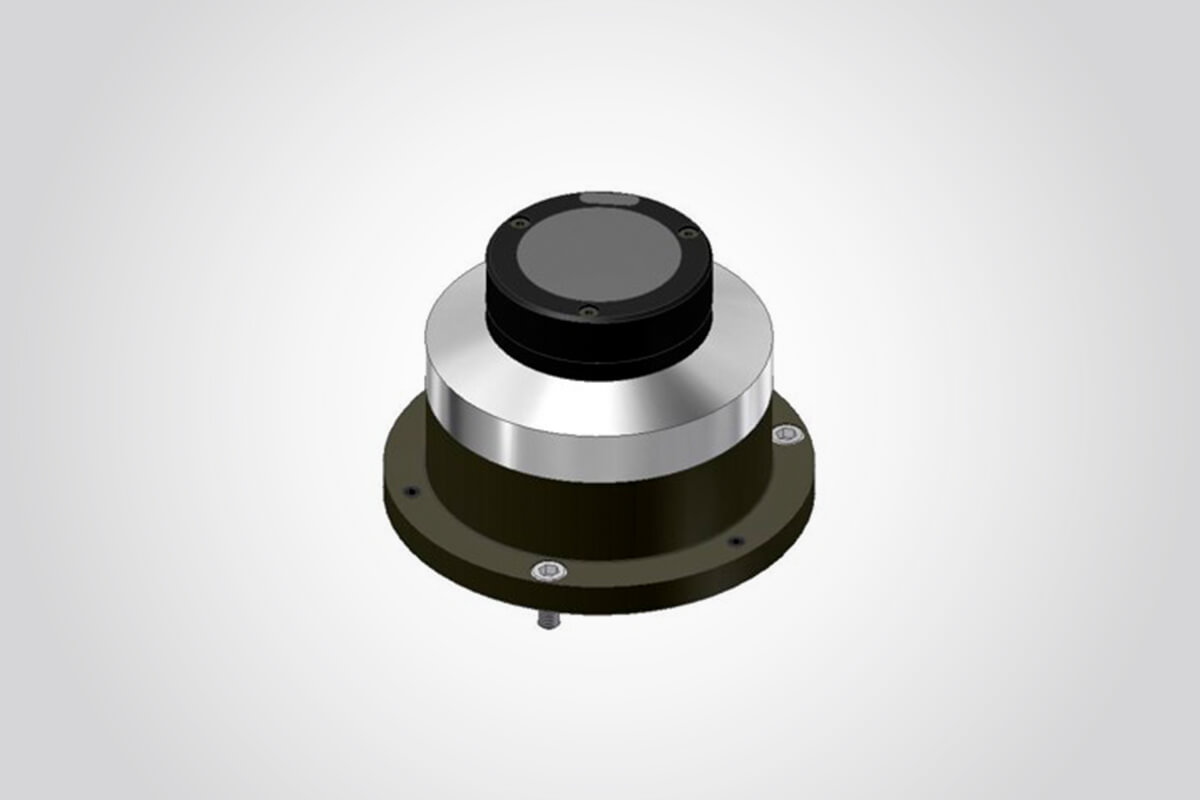

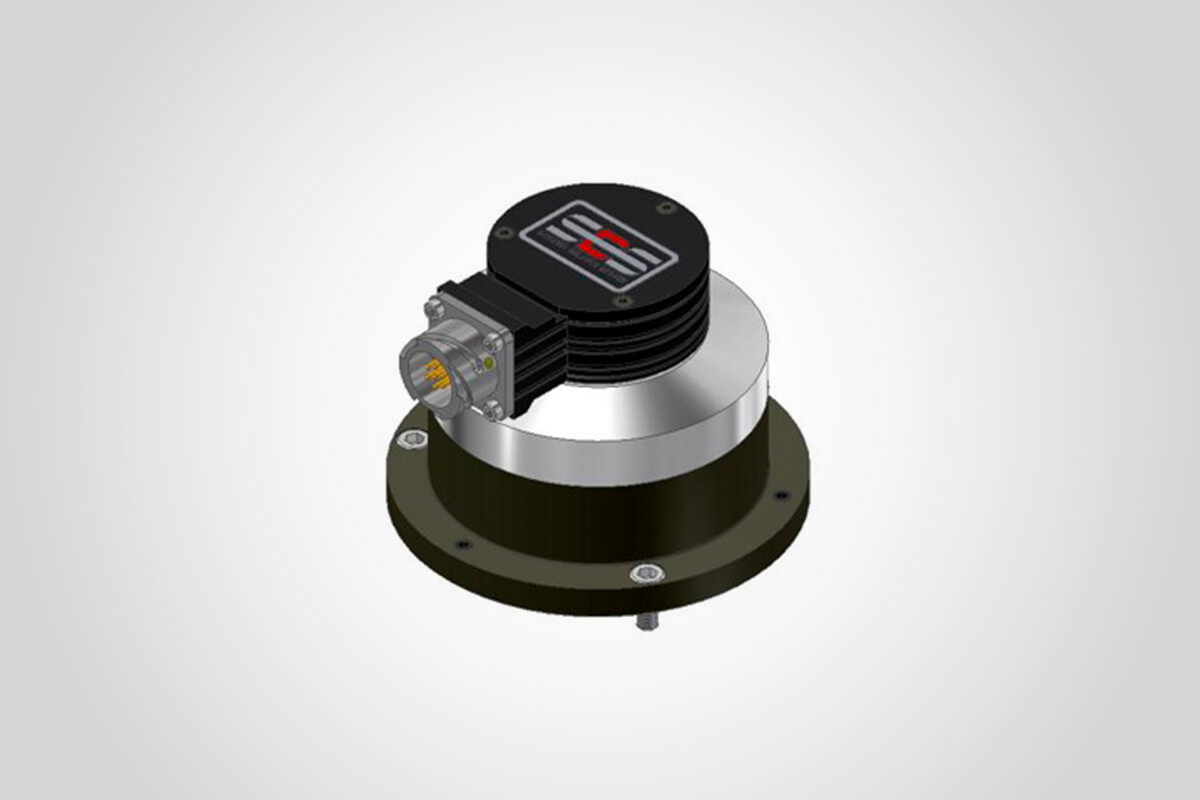

SYSTEM COMPONENTS

Computer Control features a bright graphic display in a sealed enclosure for the harshest of grinding environments. Sensor monitors vibration levels with precision accuracy. It can be mounted with the magnet supplied or the magnet easily un-screws for stud mounting. Balance Head compensates for wheel imbalance. Balance is maintained even if wheel is stopped and re-strated. Spindle Adapter attaches balancer head to the grinder. It allows easy removal of the balance head for quick wheel changes.